PerFluoroalkyl and Polyfluoro Alkyl Substances (PFAS) are vital to the semiconductor industry due to their unique and unparalleled properties. They are used throughout the entire semiconductor manufacturing supply chain. Although some PFAS pose a risk to health and the environment, they have come under increased scrutiny by regulators and government bodies around the world, unfortunately, in a very politicized way.

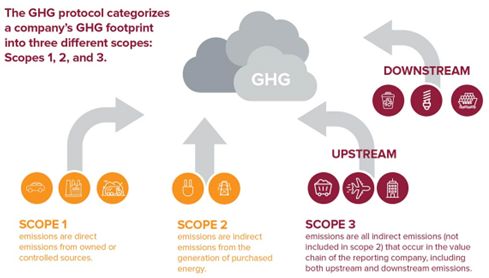

SEMI’s S23 Standard – Save Energy, Save Money, Save the Planet

The greatest potential for immediate reductions in GHG emissions in semiconductor manufacturing lies in reducing the energy used by manufacturing equipment.

Outlook for 2022: Executive Viewpoints

Each year, Semiconductor Digest turns to industry leaders and analysts to get their viewpoints on what they expect to see in the coming year in terms of critical tech and business trends. For 2022, in addition to ongoing technical advances, expect to see a focus on supply chain challenges, sustainability, the workforce shortage and reshoring.

Emerging Vacuum Challenges Posed by New Materials and Cluster Tool Architectures

New processes and materials pose many challenges for supporting vacuum equipment. Intelligent design choices can address these challenges.

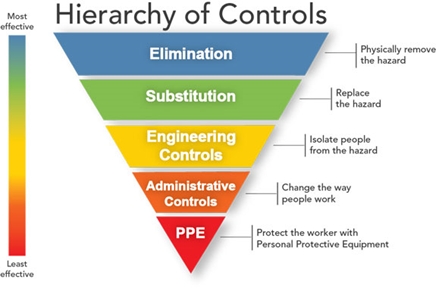

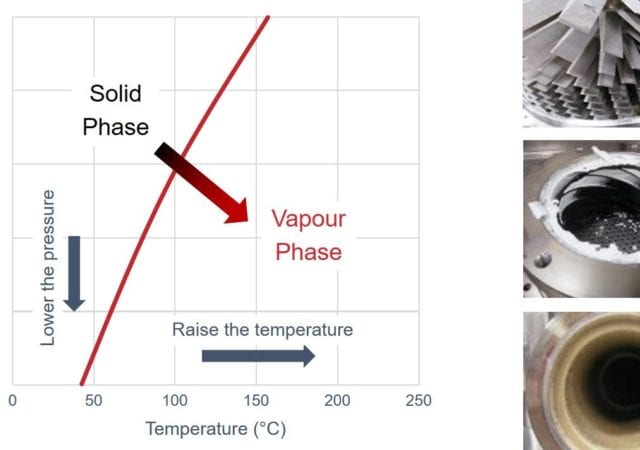

Energetic Materials in the Sub-fab: Protecting Personnel and Productivity

Most incidents with energetic materials occur in the sub-fab where material can accumulate in vacuum lines and pumps. Careless behavior can result in catastrophic failures that injure personnel, damage equipment, and halt production.

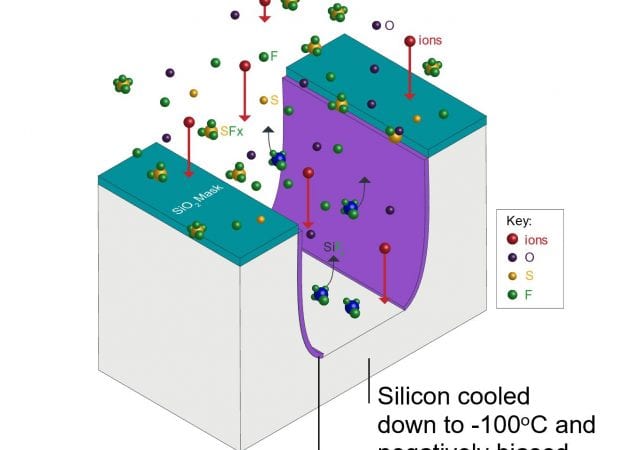

Understanding Cooling and Particulate Contamination Challenges for Next Generation ALE Technologies

Mixed-refrigerant Joule-Thomson refrigeration can provide the necessary wafer temperatures and cooling power with smaller footprint, better reliability and lower power consumption than alternative cooling technologies. Cryo-trapping can reduce particle generation by removing the water that mediates the particle formation process.

Harsh New Processes and Materials Pose Challenges for Vacuum Systems

Maximizing the productivity and profitability of the semiconductor manufacturing process requires pump designs that are optimized for the application, especially harsh applications that use condensable or corrosive gases.

Innovative Approaches to Vacuum Enable High-Volume Atomic Layer Processing

Processes such as atomic layer deposition and etch require fast, repetitive, complete exchange of gases in the process chamber. Vacuum equipment manufacturers have responded with solutions that address the challenges presented by these high flow applications.