PAUL HOFEMANN, Semiconductor Technical Expert at Mott Corporation

Managing heat in modern electronics is no longer a secondary concern: it’s a fundamental challenge that defines performance, reliability, and efficiency. As devices become more powerful, compact, and energy-intensive, traditional cooling methods struggle to keep pace. The breakdown of Dennard Scaling [1], the rise of AI chipsets with soaring thermal design powers (TDP [2]), and the increasing demand for efficiency in industries like data centers have pushed thermal management to the forefront of innovation.

Thermal challenges in semiconductor process tools

While much focus is placed on artificial intelligence and high-performance computing, the thermal challenges in semiconductor process tools—machines used to make advanced chips—are equally, if not more, complex. Extreme temperatures, angstrom-scale precision, and reactive chamber environments require careful management of heat, which must sometimes be discarded and other times carefully controlled for the process. Unlike server farms, where the primary goal is heat dissipation, semiconductor fabrication equipment requires tailored thermal solutions. These solutions not only manage excess heat but also carefully incorporate heat when needed to facilitate chemical reactions in the chip fabrication process and ensure process stability and yield.

Effective and efficient heat transfer

Thermal dynamics follows the natural laws of entropy, with heat flowing from high to low temperature through the most efficient available path. The efficiency of heat transfer depends on the medium between the hot and cool regions—whether it’s a vacuum, solid, or fluid—where one mechanism often outperforms the others under specific conditions. Effective thermal management is essential for controlling these transfer hierarchies, which includes not only the dissipation of heat but also, when necessary, containing or spreading it to maintain system stability. The thermal engineer must guide this flow, designing systems that optimize heat transfer mechanisms—conduction, convection, or radiation—based on the application or system requirements.

Thermal challenges in semiconductor equipment

Thermal management in semiconductor process tools is a high-stakes balancing act, where engineers must reconcile a maze of extreme contradictory requirements. EUV lithography, for instance, is quite literally a house of mirrors—its reflective optics, constantly bombarded by soft X-ray photons, must maintain near-room-temperature conditions with an ultra-tight temperature gradient of less than 0.05 °C/cm to preserve image fidelity. Meanwhile, producing just 15 watts of EUV photon power at the wafer started out as a CO2 laser with enough energy to power 1,000 homes, generating an immense waste heat load that must be carefully removed or repurposed.

Beyond EUV, Rapid Thermal Processing (RTP) presents its own challenges, requiring aggressive, time-sensitive temperature ramps for critical steps like annealing and oxidation. Precision motion stages depend on isothermal stability to ensure nanometer-scale repeatability, while high-density plasma etch systems must maintain uniform wafer temperatures to prevent spatial etch rate variations—especially for high-aspect-ratio features. These challenges become even more formidable in deep vacuum environments (10⁻⁶ to 10⁻⁹ Torr) or under extreme acceleration forces exceeding 5 g. Further complicating matters, traditional copper cold plates—widely used in high-performance cooling—are often unwelcome near sensitive semiconductor processes due to contamination risks.

Advantages of two-phase cooling

One of the most promising advancements in cooling technology is two-phase cooling, which utilizes the phase change of a working fluid to absorb and release heat with remarkable efficiency. Unlike conventional single-phase liquid cooling—where heat is transferred solely through conduction and convection—two-phase cooling relies on evaporation and condensation cycles to maintain stable component temperatures. This approach takes advantage of latent heat of vaporization, meaning the working fluid absorbs substantial energy as it evaporates without a corresponding temperature rise. As a result, two-phase cooling enables highly efficient heat removal from power-dense components.

The specific heat of a cooling fluid defines how much thermal energy it can absorb per degree of temperature rise. For air, this is typically around 1.2 J/L·°C, while water is much higher at 4,180 J/L·°C. This high specific heat capacity of water is the main reason liquid cooling has become a standard in data centers.

However, simply increasing fluid velocity and optimizing fluid-to-heat source mixing has practical limits. Increasing the fluid flow requires higher fan speeds or faster liquid pumping, which detracts from overall efficiency due to increased cooling systems energy consumption. This is where the future of cooling lies in two-phase systems, which offer a next-generation approach to thermal management.

The science behind two-phase systems

Two-phase systems leverage the phenomena of latent heat absorption, providing a significant leap in cooling efficiency. At atmospheric pressure, a common refrigerant like R1233zd(E) absorbs 180,000 J/L at a constant 18°C (boiling), while water is even more impressive at 2,159,000 J/L at 100°C. This means two-phase systems can absorb vastly more heat without a corresponding rise in temperature, making them ideal for isothermal cooling applications.

The ability to fine-tune boiling points by adjusting pressure in vacuum chambers allows for precise control over the cooling process. This flexibility, combined with the high latent heat absorption, positions two-phase systems as the cutting-edge solution for future cooling needs. To maximize efficiency, designs should minimize pressure drop as vapor travels to the condenser, both within the vapor chamber and through ancillary vapor lines.

In summary, two-phase systems represent the next generation of cooling technology, offering unparalleled efficiency and performance. As we push the boundaries of what’s possible in thermal management, two-phase cooling is poised to become the standard for high-demand applications.

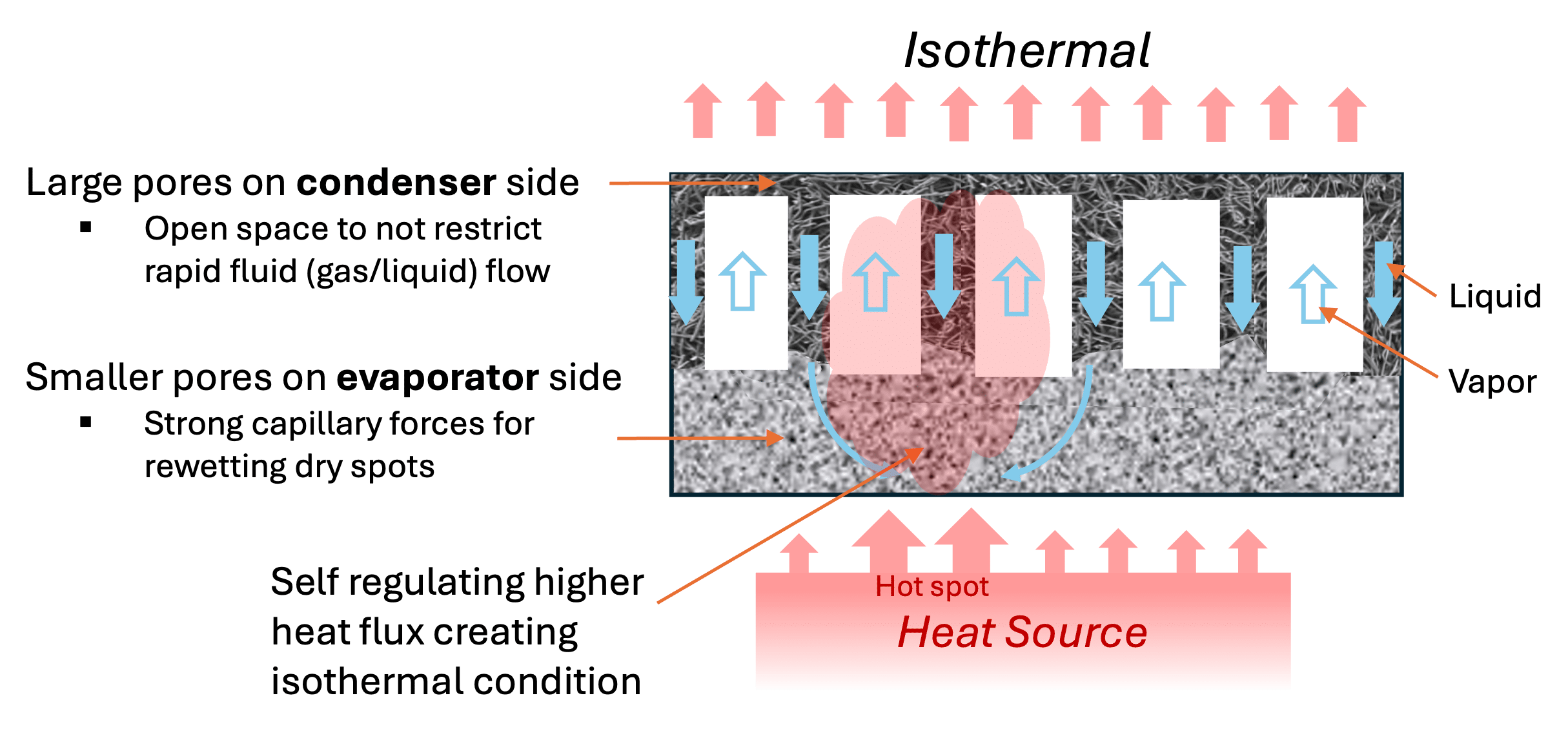

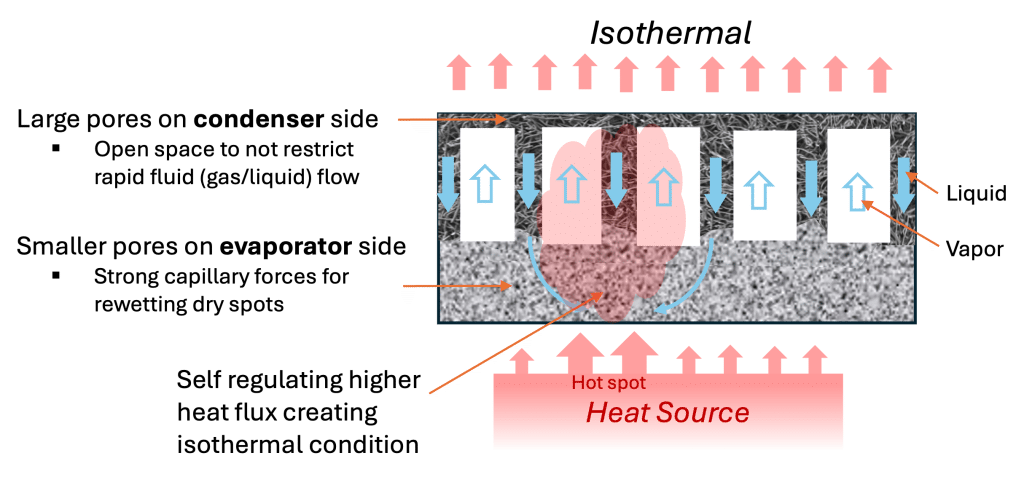

The innovative wicking structure

This whole process is particularly effective for managing transient heat loads, as the phase change rapidly dissipates localized hotspots, preventing thermal runaway and ensuring uniform temperature distribution. This makes two-phase cooling an ideal solution for high-power applications such as plasma chamber systems and lithography tools, where conventional cooling methods often rely on inefficient pre-chilled inlet fluids to “smooth out” the variable temperature topography of most heat sources.

Two-phase cooling solutions for semiconductor OEMs apply precise pore sizes of sintered metal powders and fibers (already widely used in semiconductor fabrication as specialty gas filters) to create novel wicking structures that optimize fluid movement in two-phase systems (FIGURE 1). The wicking structure needs small pores along the heat source wall to generate strong capillary forces, ensuring that liquid is drawn efficiently to the heat source for evaporation. Larger pores along the condensation wall allow for low-resistance liquid return, helping to maintain a continuous cycle of evaporation and condensation.

Click here to read the full article in Semiconductor Digest magazine.